R&D

Total Solution Company Value Engineering

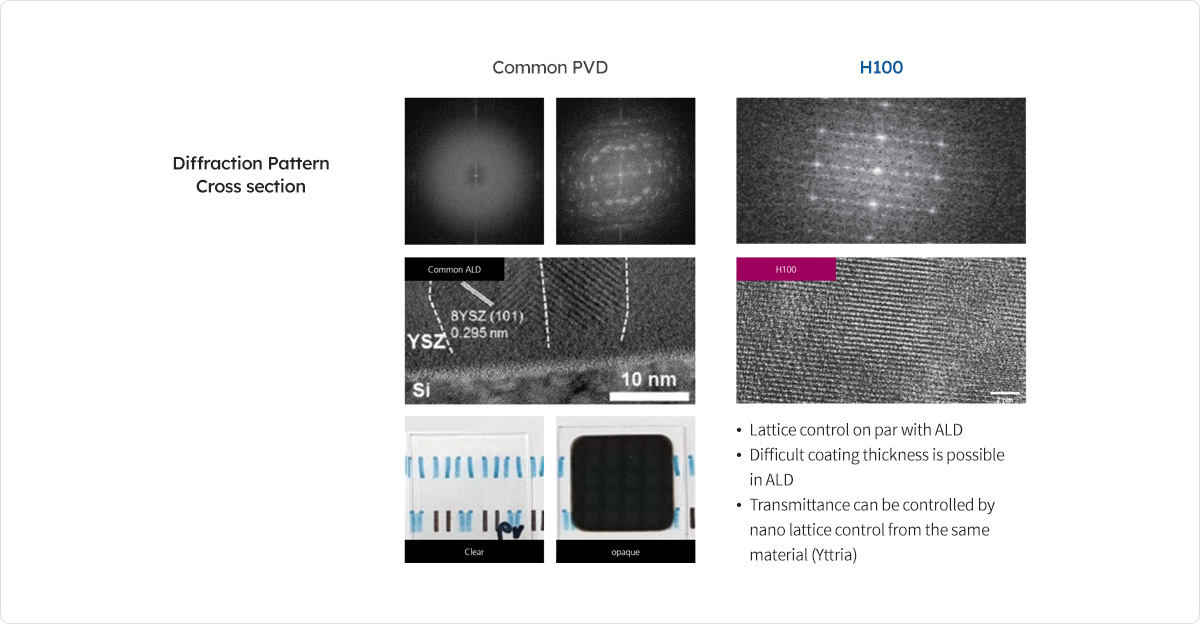

Nano Lattice Control Coating

Plasma Resistant Coating

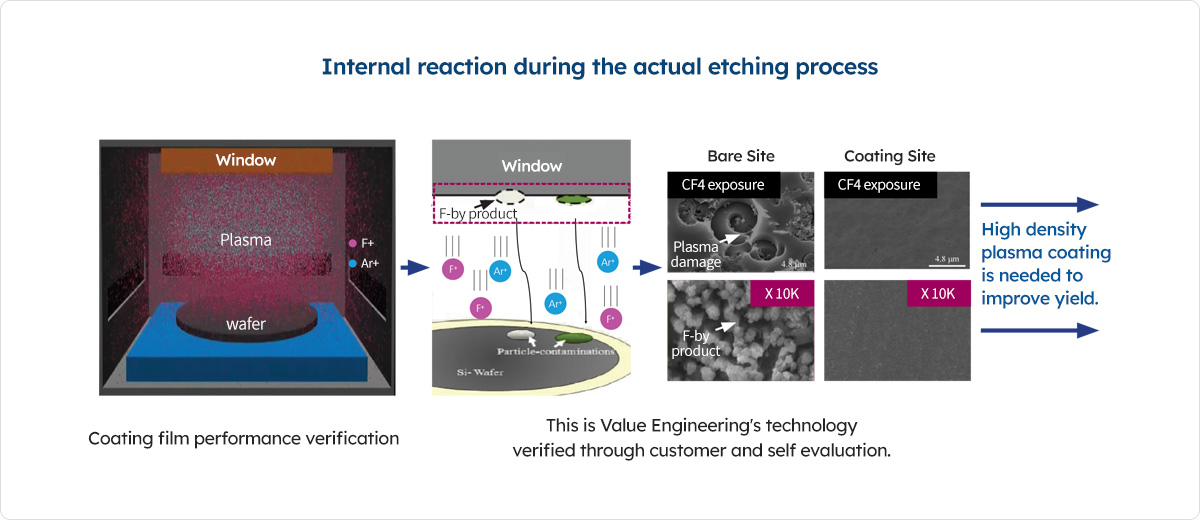

What is Plasma Resistant Coating?

Corrosion of equipment parts occurs due to exposure to plasma, etching gas, and high-temperature process temperatures,

thereby generating a large amount of contaminated particles. This is a coating to prevent the resulting decline in production yield.

thereby generating a large amount of contaminated particles. This is a coating to prevent the resulting decline in production yield.

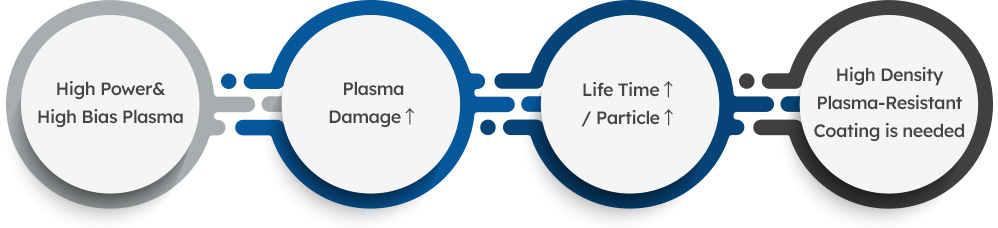

Technology Industry Background

In the case of Etching parts coatings in the current high-end market, foreign equipment manufacturers are monopolized (LAM)

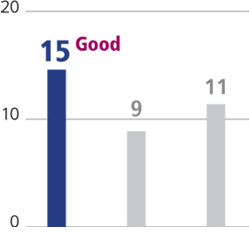

Development Performance

Characteristics of Plasma Resistant Coating Film

Hardness (GPa)

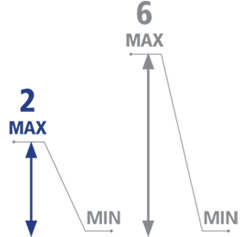

Thickness deviation (%)

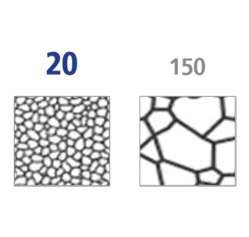

Grain Size (nm)

| E-beam | Sputter | H100, H200 | |

|---|---|---|---|

| Principle | A method of evaporating the coating material and depositing it on the substrate |

Deposits the protruding target particles by bombarding the ions in the plasma with the target material. |

Ion-assisted control + sputtering deposition → Nanolattice Control Coatings |

| Vapor Deposition | Vapor(Liquid) | Atomic | Atomic + Ionic |

| Confomality | Good | Good | Excellent |

| Adhesion to Substrate | Bad | Good | Excellent |

| Precision | Good | Good | Excellent |

| Hardness | Bad | Good | Excellent |

| Thermal Stability | Bad | Good | Excellent |

| Light Transmittance | Good | Good | Excellent |

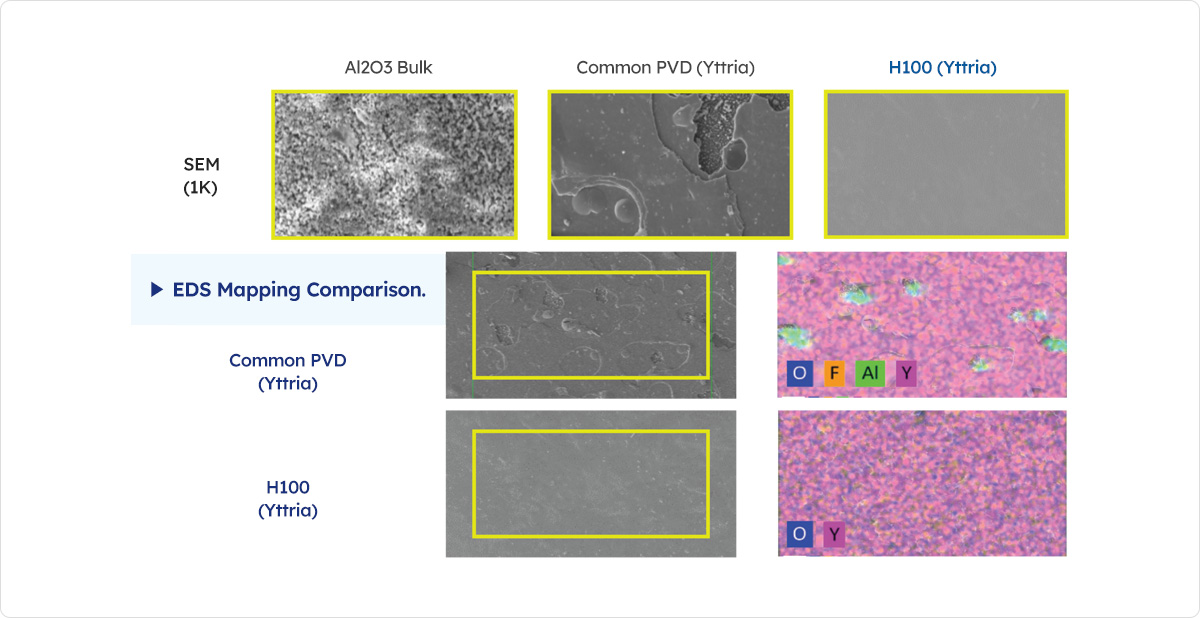

Characteristics of Plasma Resistance

Plasma Exposure Test

Nano Lattice Structure